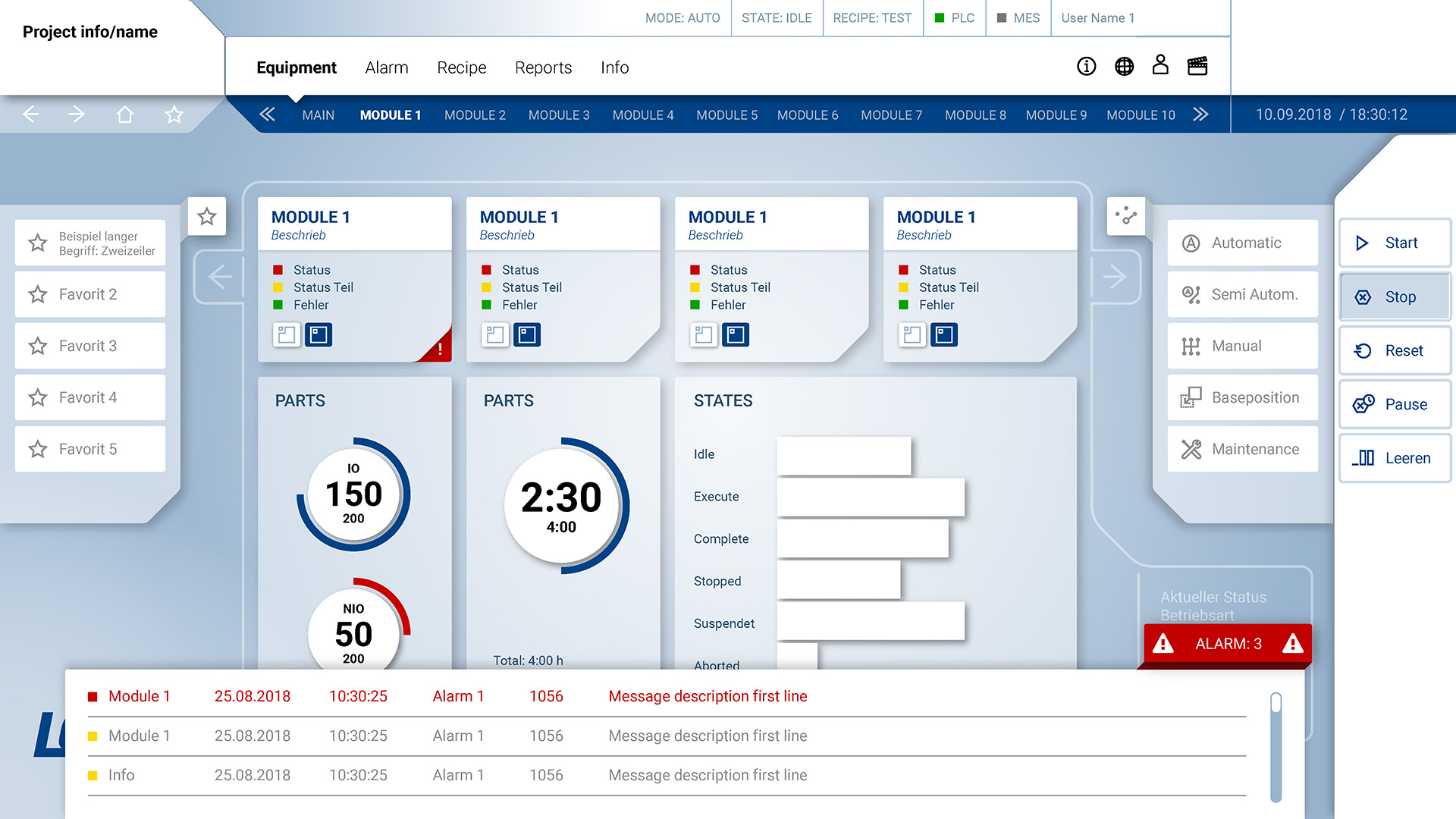

Software

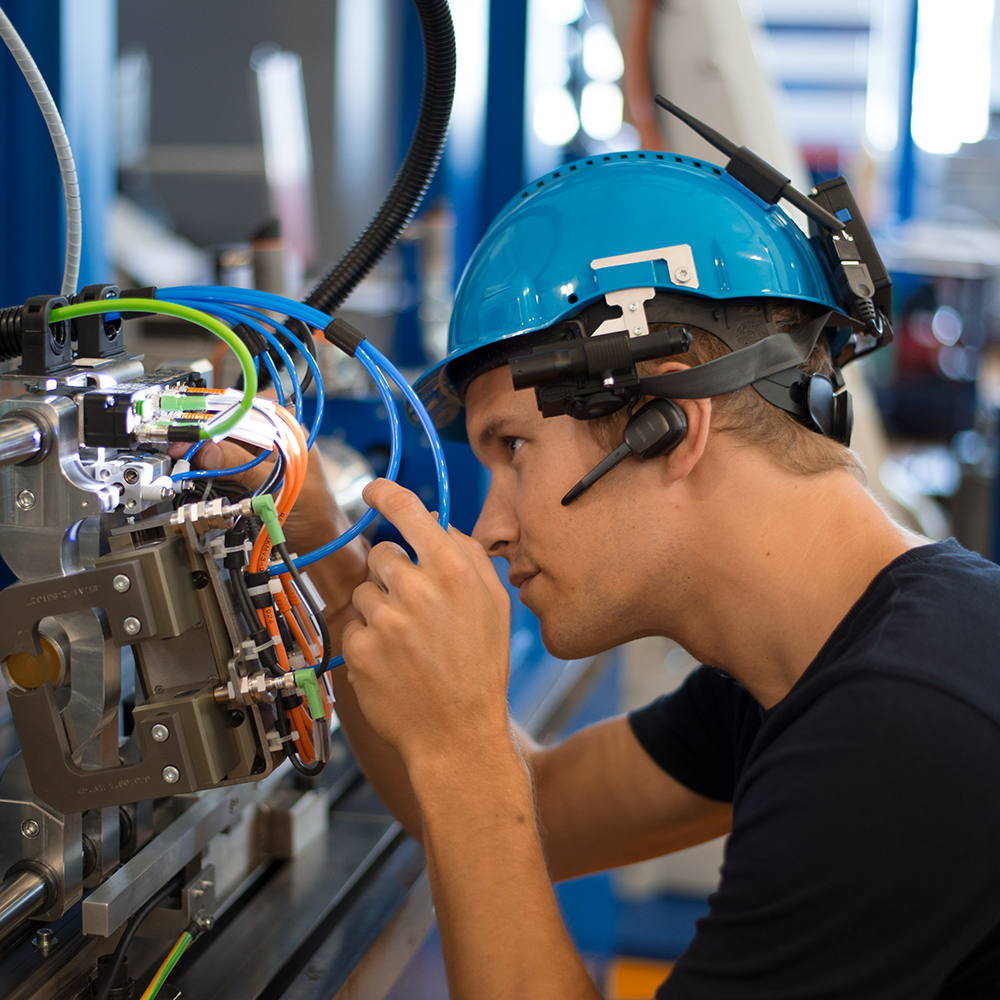

Intelligent solutions for factory automation control systems

In-house software development is the key to successful factory automation solutions. We apply both traditional and object-oriented methods. Our software team is steadily growing and gets ready for the future now!

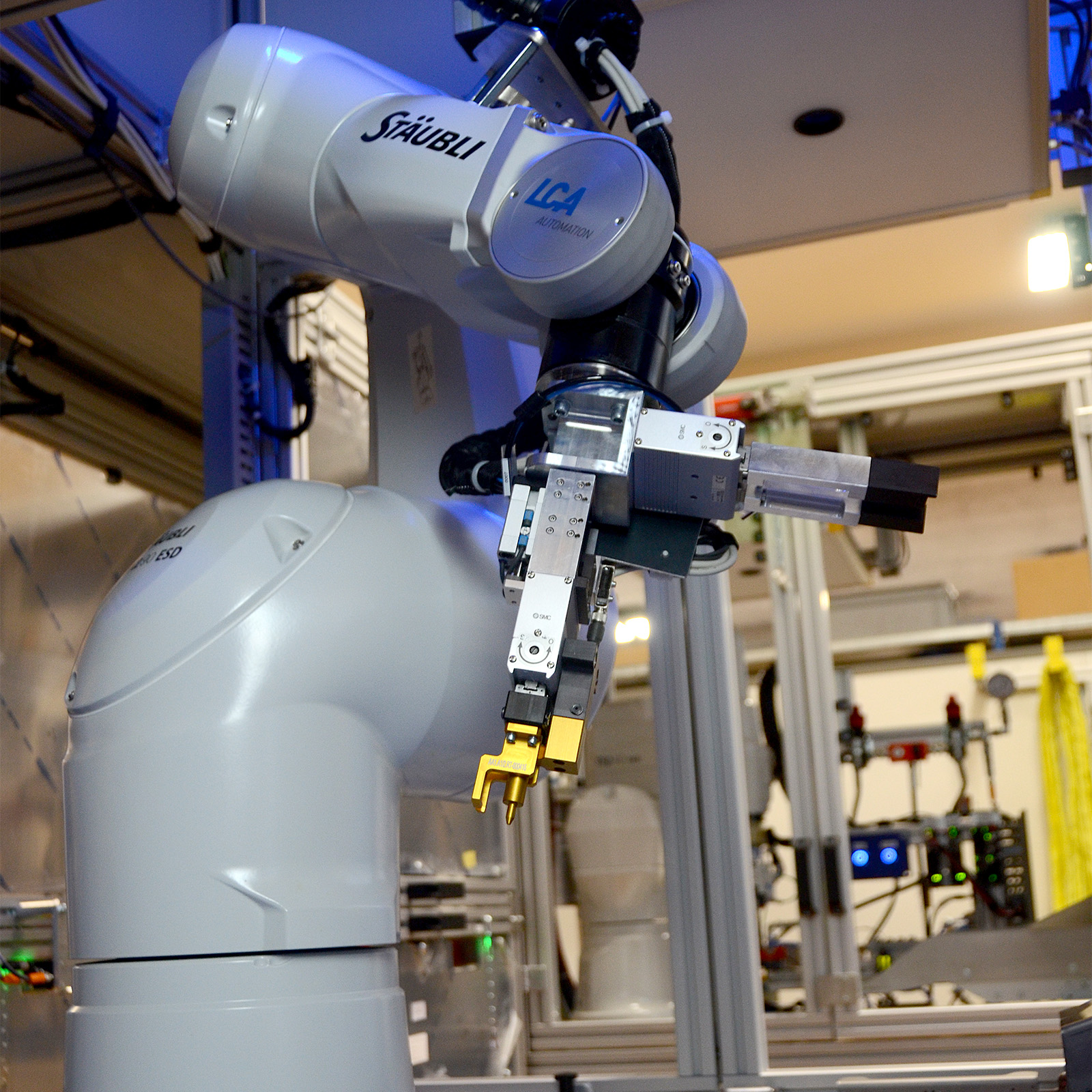

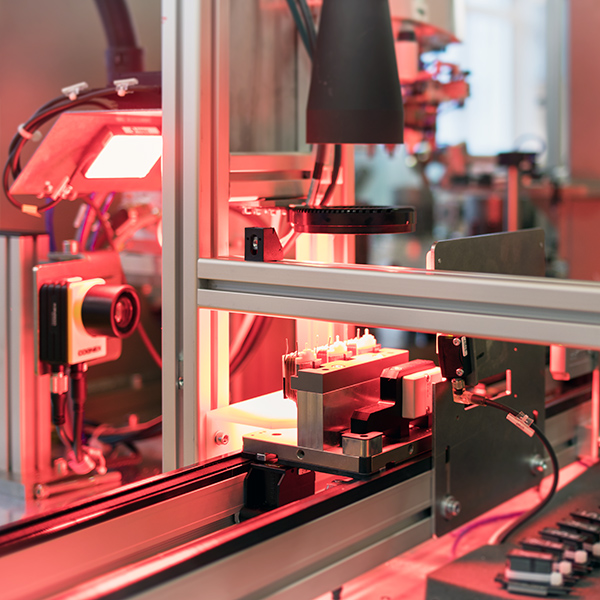

Whether it’s a conveyor system or a rotary table with parts loading by robots: our software platform can handle it elegantly. We are also familiar with state-of-the-art transport systems such as XTS and XPlanar from Beckhoff. In addition to pneumatic and electric axes, we are experienced in position-controlled hydraulic axes with several tonnes of press force. In cooperation with our process engineers, we successfully implement our customers’ requirements.

We visualize your process: data, such as force-displacement curves, can be recorded, stored and evaluated by our software.

Our core competence lies in the design of assembly lines or production systems for the automotive industry. We have successfully implemented our custom-built machines in various growing markets, such as food industry, aviation and medical.