HSC (High Speed Cutting) for metal alloys

The FP-Series milling machines were designed for high speed cutting of aluminum. The most special feature of this horizontal milling machine ist it’s 15° tilt table, enabling one operator to position and clamp the work piece. In production, the chips fall vertically onto the scrap conveyor.

Drilling and chamfering of high strength rail material

For the production of rail road switches numerous screw holes are needed. It is exclusively for this process that we developed a 6500mm long machine tool including a high power, fast clamping system. The rail can be loaded by electric rolls and positioned on the clamping table. The special drill, which machines the holes and chamfers in and out, is operated by a high torque spindle, linked to the automated tool change system.

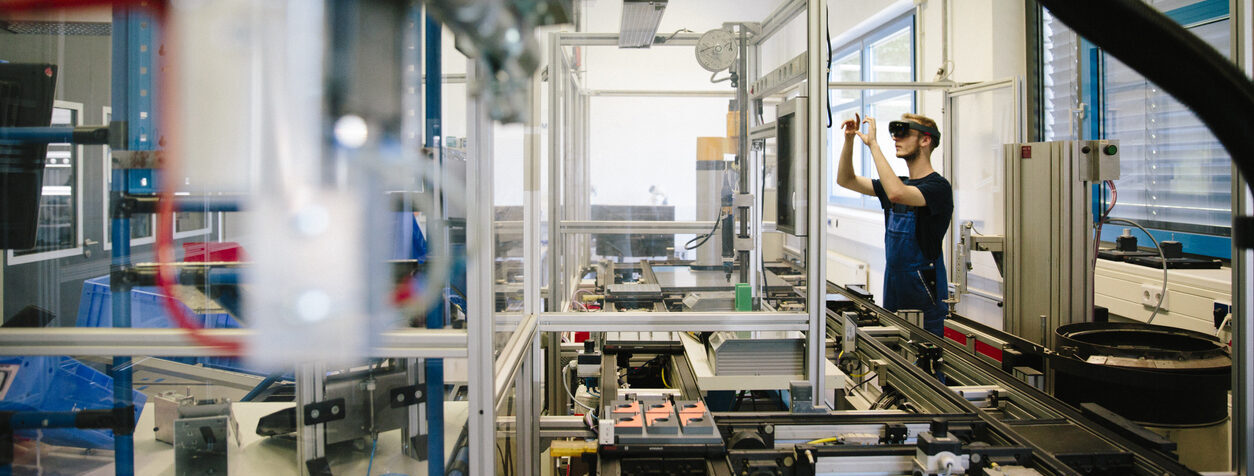

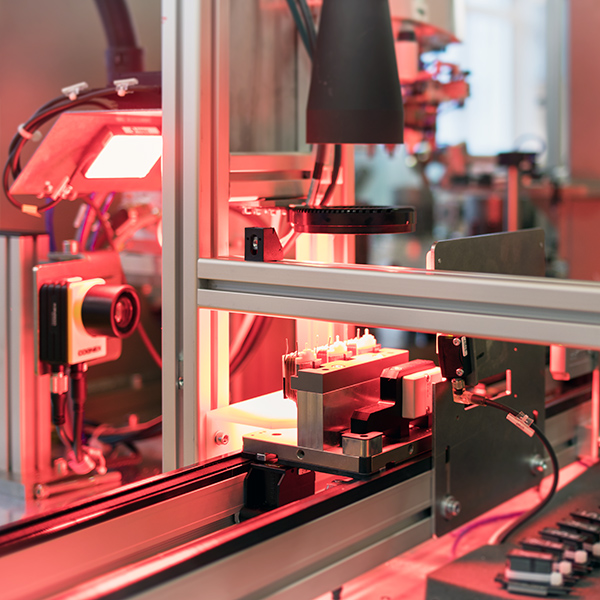

Flexible manufacturing cell

A combination of all elements of factory automation technology, interlinked by handling robots.